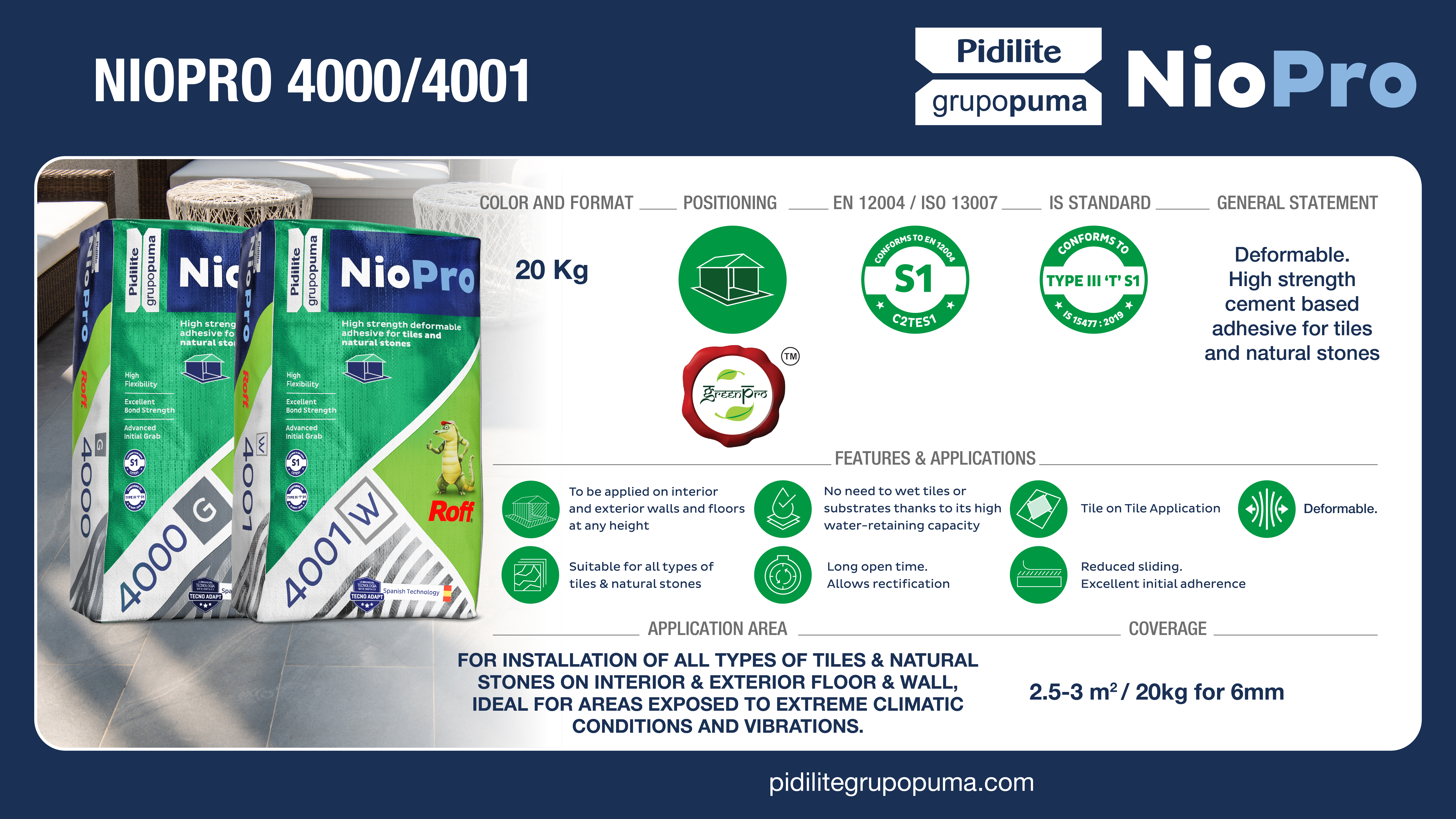

NioPro 4000/4001

NioPro 4000/4001

High strength deformable adhesive made of mixed bonding agents with reduced sliding and expanded open time, for installation of all types of tiles & natural stones on interior & exterior floor & wall; ideal for areas exposed to extreme climatic conditions and vibrations.

Additional information

Technical Caracteristics

Product based on high resistance cement, selected aggregates, additives and synthetic resins, which give

excellent bonding, good workability and resistance to ageing.

Advantages and Uses

- To be applied on interior and exterior walls and floors.

- Suitable for all types of tiles & natural stones.

- No need to wet tiles or substrates thanks to its high water-retaining capacity.

- Long open time. Allows rectification.

- Tile on Tile Application.

- Reduced sliding. Excellent initial adherence.

Suitable Substrates

- Conventional cement-based substrates.

- Indoor and outdoor cladding and flooring of tiles and stones.

- Substrates must be resistant, stable, sound and clean, free of dust, demolding agents, organic products, etc.

- All substrates must have the appropriate flatness. Otherwise, smooth down up to 5 mm with the same product 48 hours prior to bonding.

- For greater thickness, use traditional dry mortars or levelling paste.

- In case of hot or windy weather conditions or when applying over absorbent substrates, it is advisable to wet the substrate and wait till the thin layer of water disappears.

- Do not apply on clay or on paint.

Application Procedure

- Add water and mix mechanically until it takes on an even and workable consistency.

- Let the mixture stand for 5 minutes and remix.

- Spread the mixed product on the substrate with a trowel to a maximum surface area of 2m².

- Spread with a notched trowel to adjust thickness (see chart).

- Lay the tiles/natural stones, press and make small rotation movements to ensure that the glue gets in total contact with both surfaces.

- Observe construction joints (expansion, contraction, fraction, perimeter corner joints) and the joints between the cement slabs (minimum 2 mm).

- Joints should be grouted 24 hours after if on vertical surfaces, and 48 hours after if on floorings. Use Roff Tile grouting range depending on the type of joint.

NOTE

For better results lay tiles as soon as possible after spreading.

Recommendations

- Do not apply below 5ºC nor above 35ºC.

- Do not apply when there is a risk of frost, rain, strong wind or direct sunlight.

- Do not apply in areas where water may accumulate.

- Under extreme weather conditions (gusty winds or high temperatures) drying may occur faster.

- On interior floorings larger than 15 m², it is advisable to keep a free perimeter expansion joint between the floor and the wall or pillar, hidden by a baseboard.

- For plywood, drywall, glass or metal substrate & artificial stone, use Roff Masterfix.

- The swimming pool can be refilled after 7 days of applying the adhesive.

- The watertightness of the swimming pool must be ensured by the filling to check for leaks.

Packaging and Storage

20 kg

Coverage:

2.5-3 m2/20 kg for 6 mm thickness

Shelf life:

year in sealed original packaging, sheltered from weather conditions and humidity.

Technical data

Statistical data obtained under standard conditions

| Aspect | Grey/ White Powder |

| Apparent density of powder | 1.40 ± 0.2 g/cm3 |

| Density of mixed product | 1.6 ± 0.2 g/cm3 |

| Mixing Ratio (Powder : Water) | 1 : 0.24 (Grey) / 1 : 0.30 (White) |

| Adjustment time | Approx. 30 min. (depending on weather conditions) |

| Open Time | Approx. 30 min. (depending on weather conditions) |

| Pot Life | Approx. 2 hours (depending on weather conditions) |

PERFORMANCE PROPERTIES AS PER EN 12004 (C2 TE S1)

| TESTING PROPERTIES | REQUIREMENT | TEST RESULT |

| Initial tensile adhesion strength | > 1 N/mm2 | Complies |

| Tensile adhesion strength after water inmersion |

> 1 N/mm2 | Complies |

| Tensile adhesion strength after heat ageing | > 1 N/mm2 | Complies |

| Tensile adhesion strength after freeze-thaw cycles |

> 1 N/mm2 | Complies |

| Extended open time at 30 minutes (E) | > 0.5 N/mm2 | Complies |

PERFORMANCE PROPERTIES AS PER IS 15477:2019 (TYPE 3 `T´ S1)

| TESTING PROPERTIES | REQUIREMENT | TEST RESULT |

| Tensile Adhesion at dry Condition, after 28 days |

> 1.5 N/mm2 | Complies |

| Tensile Adhesion at Wet Condition | > 1.0 N/mm2 | Complies |

| Shear Adhesion at Dry Condition | > 1.5 N/mm2 | Complies |

| Shear Adhesion at Wet Condition | > 1 N/mm2 | Complies |

| Shear Adhesion at Heat Ageing | > 1 N/mm2 | Complies |

| Deformability | > 2.5 mm & < 5 mm | Complies |

Legal Disclaimer

The instructions for use are given according to our tests and knowledge and do not imply any commitment by Pidilite Grupopuma nor free the consumer from the examination and verification of the products for their correct use. Claims must be accompanied by the original packaging to allow a proper traceability.

Pidilite Grupopuma Manufacturing Ltd. is not responsible, in any case, for the application of its products or constructive solutions carried out by the application company or other parties involved in the process and / or execution of the work, limiting the responsibility of Pidilite Grupopuma Manufacturing Ltd exclusively to the damages directly attributable to the supplied products, individually or integrated in systems, due to failures in their manufacturing process. In any case, the drafter of the work project, the technical management or the person responsible for the work, or collaterally the application company or other parties involved in the process and / or execution of the work, must ensure the suitability of the products addressing the characteristics of them, as well as the conditions, support and possible pathologies of the work in question. The values obtained by Pidilite Grupopuma Manufacturing Ltd products or its constructive solutions that, as the case may be, are determined by the EN & IS standards or any other regulation that applies to it in each case refers exclusively to the conditions specifically stipulated in said regulation and that are referred to, among others, to certain characteristics of the support, humidity and temperature conditions, etc. without being them required in the tests obtained under different conditions, all in accordance with the relevant regulation.

Notas

The instructions for use are given according to our tests and knowledge and do not imply any commitment by GRUPO PUMA nor free the consumer from the examination and verification of the products for their correct use. Claims must be accompanied by the original packaging to allow a proper traceability.

GRUPO PUMA is not responsible, in any case, for the application of its products or constructive solutions carried out by the application company or other parties involved in the process and / or execution of the work, limiting the responsibility of GRUPO PUMA exclusively to the damages directly attributable to the supplied products, individually or integrated in systems, due to failures in their manufacturing process.

In any case, the drafter of the work project, the technical management or the person responsible for the work, or collaterally the application company or other parties involved in the process and / or execution of the work, must ensure the suitability of the products addressing the characteristics of them, as well as the conditions, support and possible pathologies of the work in question.

The values obtained by GRUPO PUMAS's products or its constructive solutions that, as the case may be, are determined by the EN standards or any other regulation that applies to it in each case refers exclusively to the conditions specifically stipulated in said regulation and that are referred to, among others, to certain characteristics of the support, humidity and temperature conditions, etc. without being them required in the tests obtained under different conditions, all in accordance with the relevant regulation.